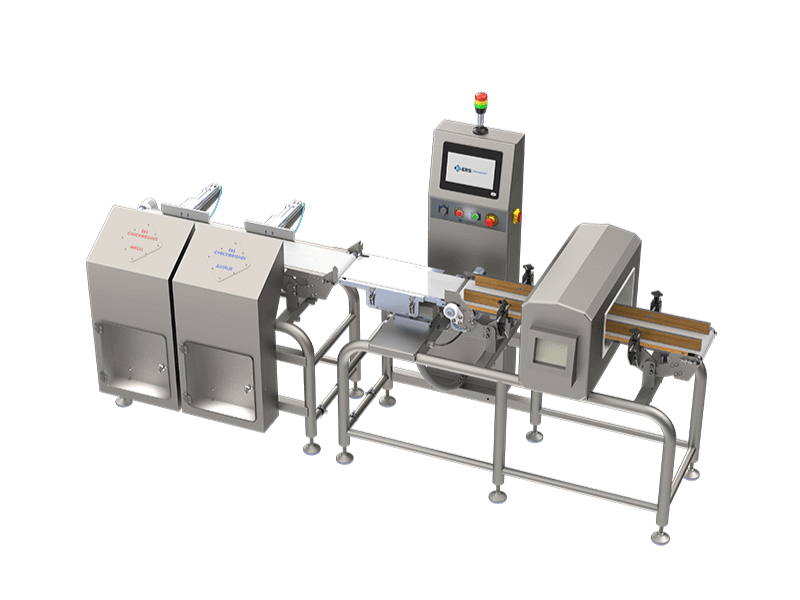

Combined System

Our combined system, which integrates the checkweigher (weight control scale) and metal detector, ensures high efficiency and security on production lines. While accurately measuring the weight of packaged products, it also detects and removes metal foreign objects, providing your products with complete quality assurance. It is an ideal solution for meeting the high precision and security requirements in the food processing, automotive, pharmaceutical, and packaging industries.

Checkweigher (Weight Control Scale)

The checkweigher precisely measures the weight of packaged products and automatically detects weight deviations from the specified range, rejecting faulty products. This process minimizes human errors and enhances production efficiency while improving quality. Automating the weighing process reduces labor costs and speeds up the production line.

Metal Detector

The metal detector in the combined system detects metal particles in packaged products and instantly rejects faulty items. It is a critical tool for preventing metal contamination before it reaches consumers, ensuring food safety and product quality. The detector has high sensitivity and can detect a wide range of metals (iron, stainless steel, aluminum), ensuring only the highest-quality products reach consumers.

Advantages of the Combined System:

- High Efficiency and Precision: Both weight control and metal detection increase security and quality on production lines.

- Automated Processes: It eliminates human errors, and automatic rejection reduces the likelihood of mistakes in production.

- Improved Quality Control: The integration of both systems ensures quality control at every stage of production.

- Low Labor Costs: Automation reduces labor costs and increases operational efficiency.

- Safe Product Distribution: The metal detector detects potential hazards in products before they reach the consumer, ensuring safe distribution.

Our combined checkweigher and metal detector system provides a reliable, efficient, and cost-effective solution to optimize your packaging and quality control processes. You can review our products to find the model that best suits your needs and contact us for detailed services.